From old to new

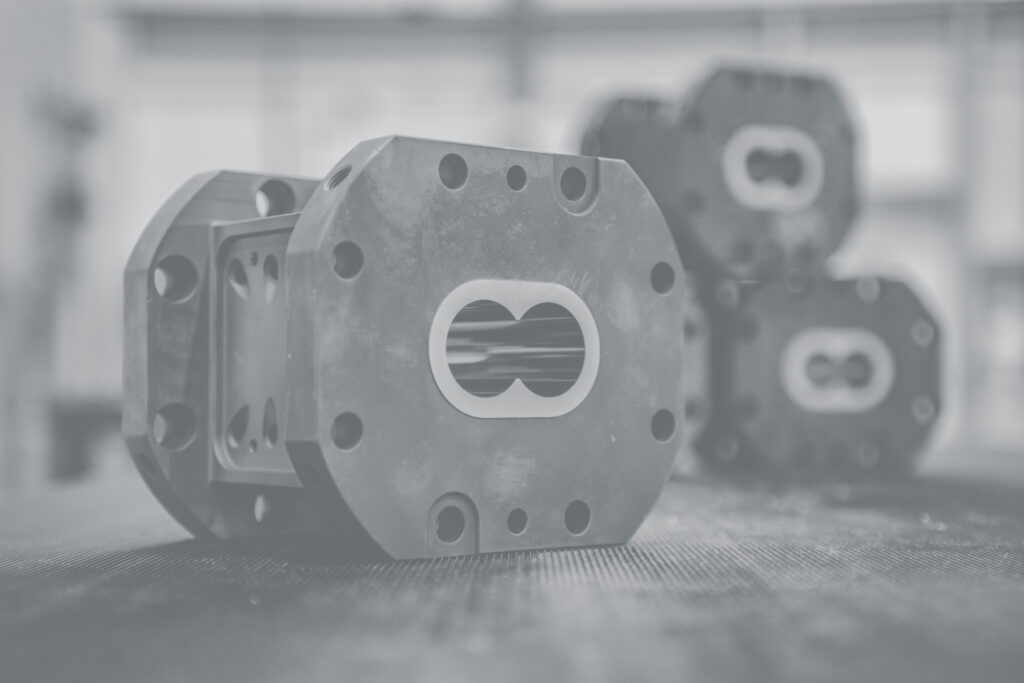

A second life for your extruder barrel

Extruder barrels generally have a long service life, but internal wear eventually necessitates replacement. For full-body barrels, this means the entire housing must be replaced, even if the outer casing and cooling are still in excellent condition.

SPS | Solids Process Solutions, in partnership with Extruder Experts, offers an innovative revision process for worn extruder barrels in co-rotating twin-screw extruders.

40% Cost Savings

This revision method delivers up to 40% cost savings compared to purchasing a completely new barrel and supports a more sustainable operation by giving high-quality machine components a second life instead of discarding them.

The revision process includes the following steps:

- Inspection of the used extruder barrel

The process begins with a thorough inspection to determine the extent of wear and assess the cooling channels. - Sandblasting and removal of the liner

The worn liner is removed with a hydraulic press, and the barrel is sandblasted to clear old coatings and contaminants, creating a clean base for the new liner. - Production of the new liner

A new liner, custom-made from wear-resistant special steel, is then manufactured to exact specifications. - Insertion of the new liner

In the heated barrel, the cooled new liner is carefully and precisely inserted to ensure optimal fit and functionality. - Grinding the liner

Finally, the barrel is ground to achieve a smooth surface, giving the entire unit a renewed, “like-new” appearance.

Would you like to find out if your extruder barrels can undergo revision? Contact SPS | Solids Process Solutions. Contact us. We are happy to help you find the most sustainable solution to keep your extrusion process up-to-date.

A WIDE RANGE OF SOLUTIONS

SPS | Solid Process Solutions offers a wide range of equipment for dosing, extruding, granulating, and inspecting. Depending on your specific needs, we will find the right and cost-effective solution.